Best quality Flow Control Valve - Grooved fire protection butterfly valve – Jinbin Valve

Best quality Flow Control Valve - Grooved fire protection butterfly valve – Jinbin Valve Detail:

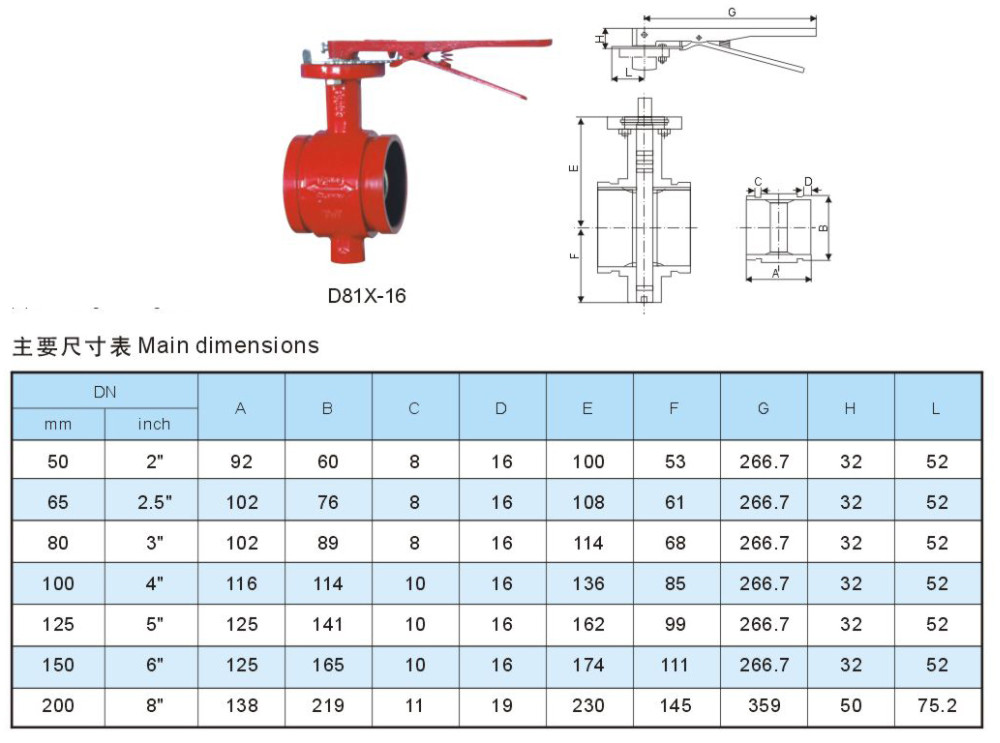

Grooved end fire protection butterfly valve

Size: 2”-12”/ 50mm –300 mm

Design standard: API 609, BS EN 593.

Face-to-Face dimension: API 609, DIN 3202 k1, ISO 5752, BS 5155, MSS SP-67.

Flange Drilling: ANSI B 16.1, BS4504, DIN PN 10 / PN 16.

Test: API 598.

Epoxy fusion coating.

Different lever operator.

|

Working Pressure |

10 bar / 16 bar |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, Oil and gas. |

|

Parts |

Materials |

|

Body |

Cast iron / Ductile iron |

|

Disc |

Nickel ductile iron / Al bronze / Stainless steel |

|

Seat |

EPDM / NBR / VITON / PTFE |

|

Stem |

Stainless steel / Carbon steel |

|

Bushing |

PTFE |

|

“O” ring |

PTFE |

|

Pin |

Stainless steel |

|

Key |

Stainless steel |

Technical data:

Structure and application:

Fire butterfly groove between the United States and Germany are the introduction of similar design and manufacture of advanced products and a series of new connection valves.It has installed express,simple,simple,safe,reliable,not subject to restrictions on the installation site,piping and valves to facilities maintenance,noise and vibration have a certain perspective of the scope has to overcome the pipelines to connect the different axis arising from poor imitation to solve the temperature difference have advantage.

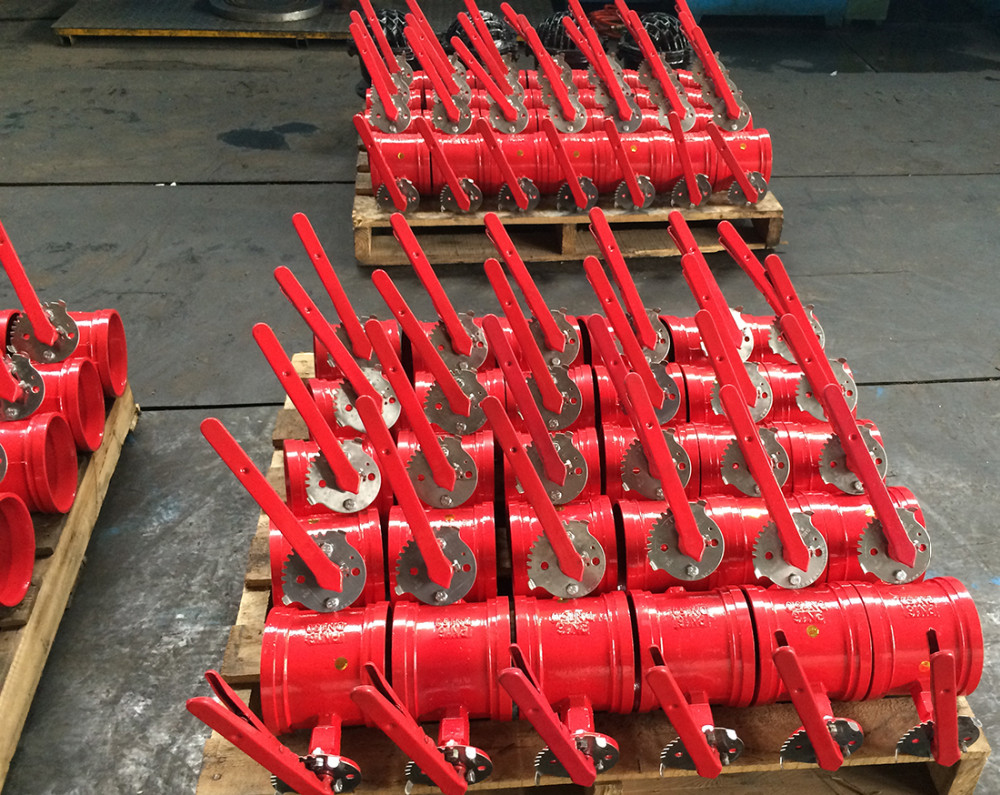

Product detail pictures:

Related Product Guide:

RHI Magnesita (LON:RHIM) Stock Rating Reaffirmed by Peel Hunt | Flange Spring No Return Check Valve

PARNABY CYCLONES 100tph sized coal Modular Transportable Dense Medium Drum Module | Flange Spring No Return Check Valve

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Best quality Flow Control Valve - Grooved fire protection butterfly valve – Jinbin Valve , The product will supply to all over the world, such as: Orlando, South Africa, Vietnam, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.