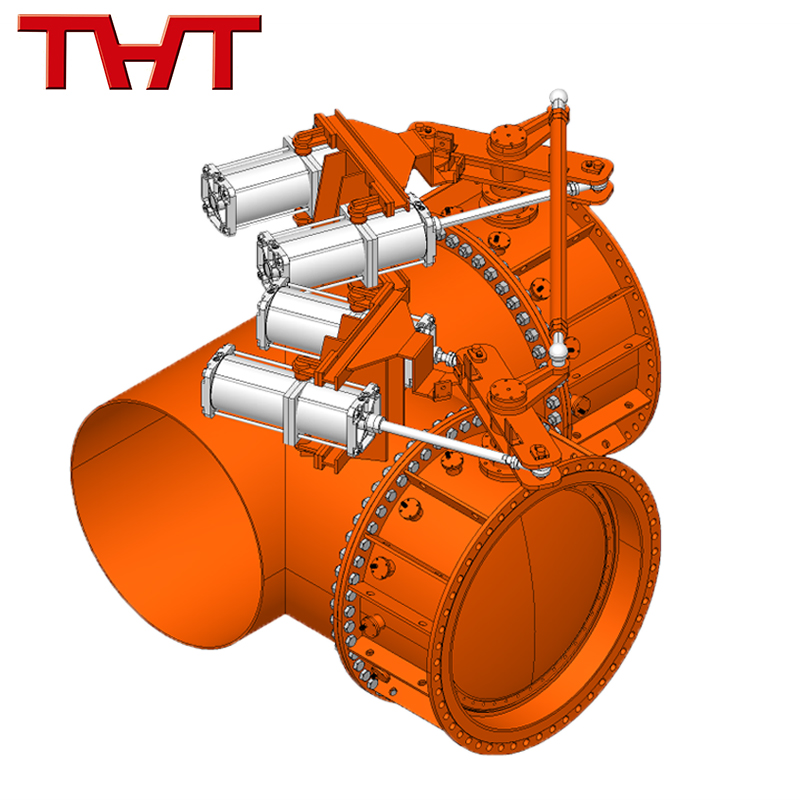

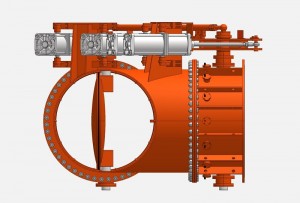

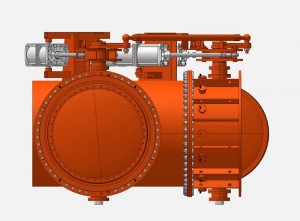

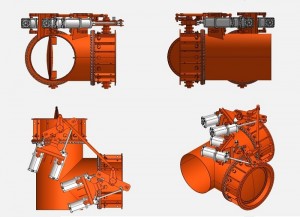

THREE-WAY BYPASS SYSTEM DAMPER VALVE

Three-way bypass valve

It is a reversing device for flue gas and air (or gas fuel)

used in regenerative industrial kilns.

The three-way bypass damper valve includes two valve body, two valve disc, two valve seat,one tee, and 4 cylinder. The valve body is divided into three cavities A, B, and C that are connected to the outside by the valve plate seat. A sealing material is installed between the valve body and the valve plate seat. The air damper plate in the cavity is connected to the cylinder through a connecting shaft. By changing the position of the valve plate, the flow direction of gas in the pipeline can be changed; Due to the heat exchange through the thermal storage body, the working temperature of the reversing valve is relatively low, and there are no special requirements for the material of the reversing valve.

However, due to the requirements of continuous production, the reversing valve needs to overcome the wear and tear caused by dust in the flue gas and the corrosive effects. The mechanical parts need to ensure the wear and tear caused by frequent switching of components, which has required high reliability and working life.

Live video

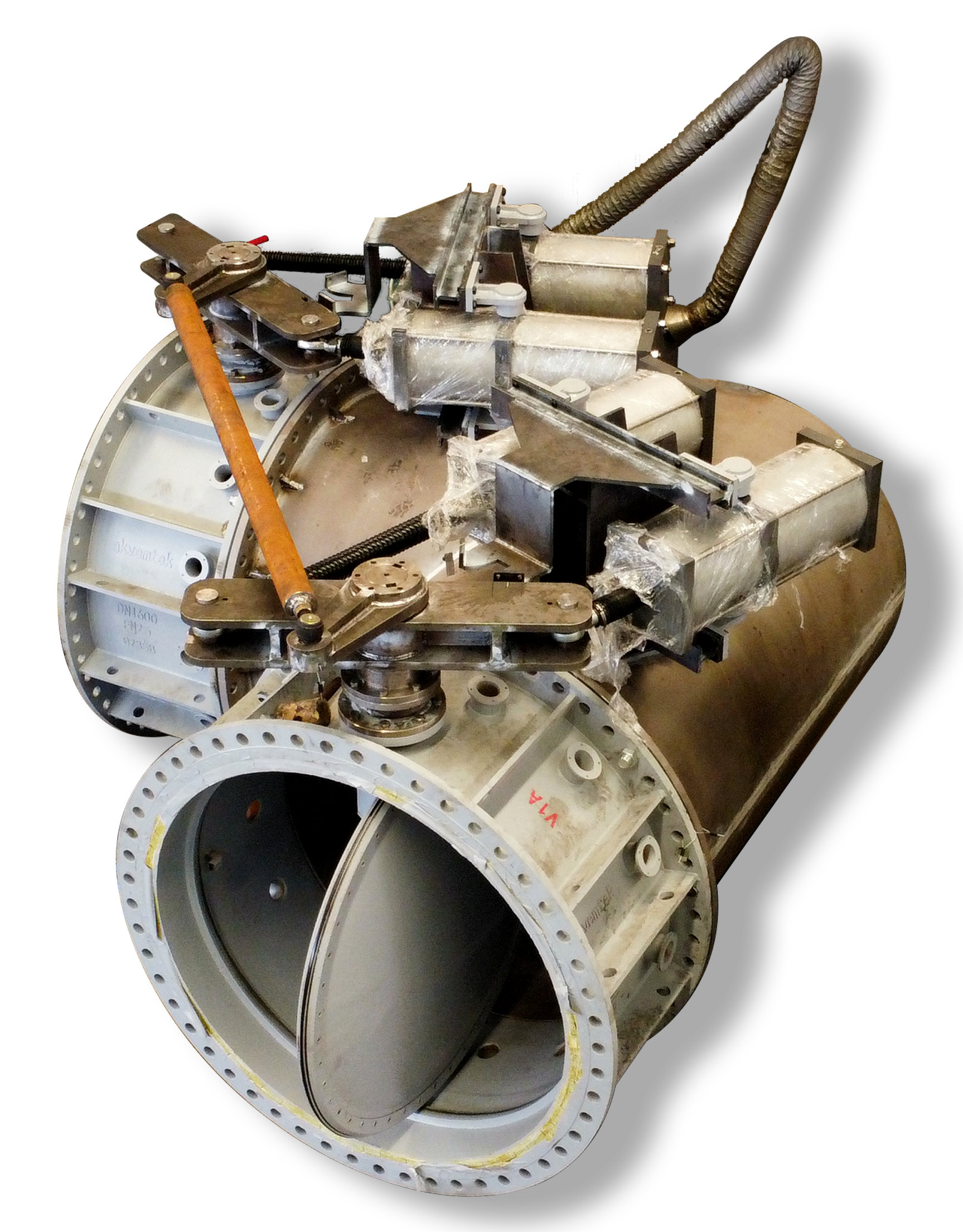

From production to completion, high quality valves

Production process···

①Raw material UT test

• All raw materials undergo 100% NDT, which have NDT report when coming into workshop.

②Laser cutting

• By using a fully automatic feeding and cutting laser cutting machine, all steel structural components can be cut with high precision by importing CAD production drawings.

③Welding

• Combination of automatic welding and manual welding.

④Machining

• CNC machining to ensure accuracy.

⑤Assembling

• Assemble according to the drawings and function 100% before packing.

⑥Painting&packing

• Spray paint according to the customer's color requirements and package according to standard sea transportation.

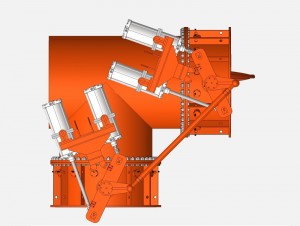

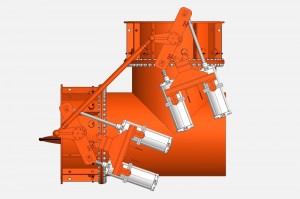

Product details···

—Quality of finishing

Three way butterfly valve bypass part <<<

Inspection package <<<