Factory Free sample Swing Type Check Valve - High temperature round Refractory Lined Damper Valve – Jinbin Valve

Factory Free sample Swing Type Check Valve - High temperature round Refractory Lined Damper Valve – Jinbin Valve Detail:

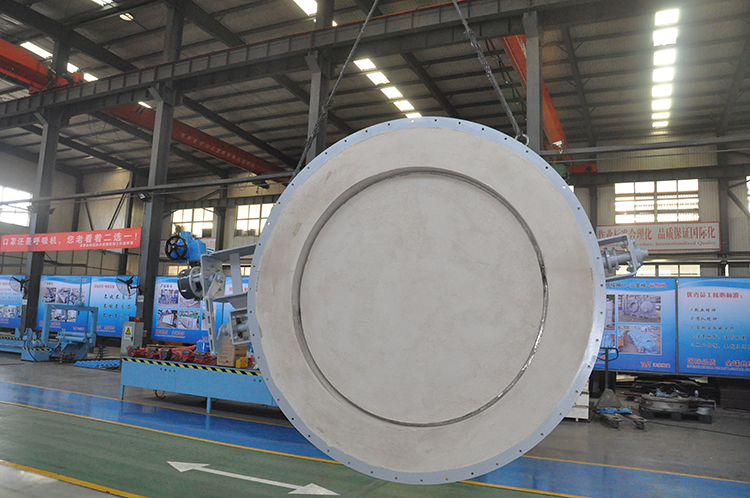

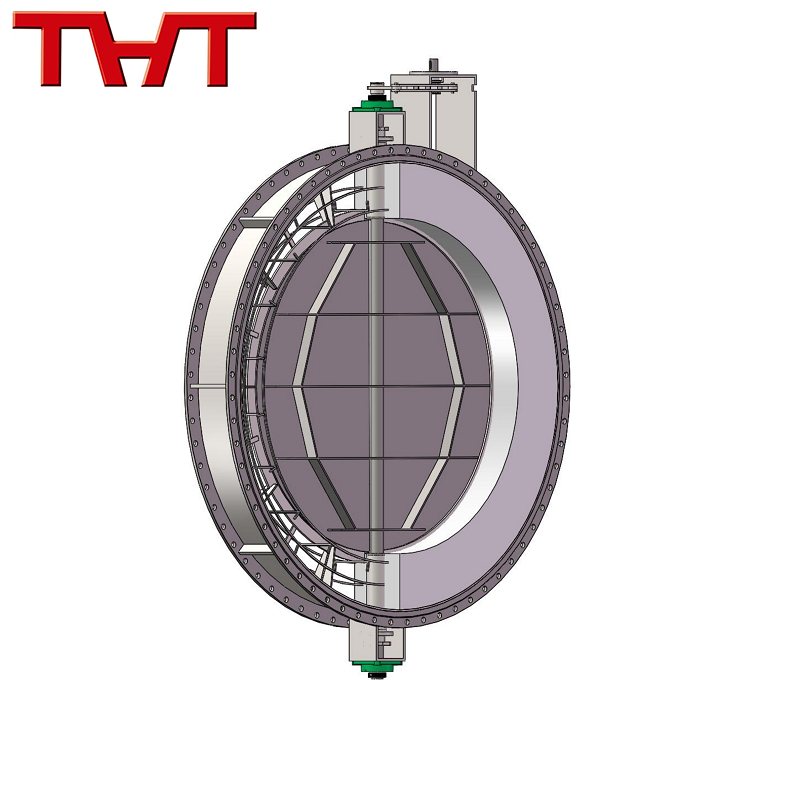

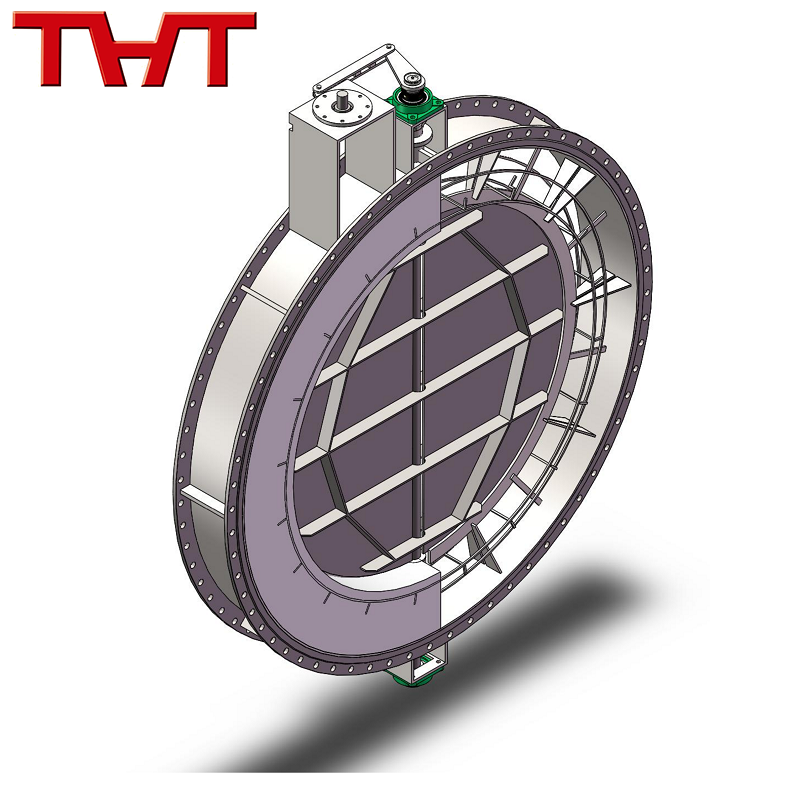

High temperature round Refractory Lined Damper Valve

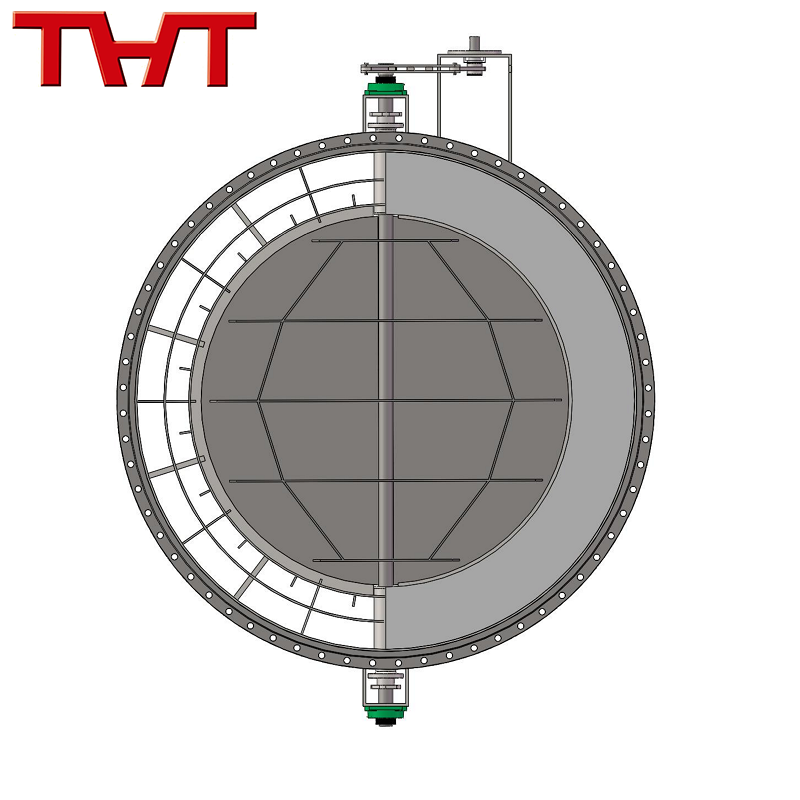

The High temperature Refractory Lined Damper Valve can be used with manual worm gear, pneumatic or electric actuators, and radiator is installed to protect the electric and pneumatic actuators and prolong the service life of the valve. It is widely used in metallurgy, heat treatment, industrial furnace, petroleum, chemical industry, cement, electric power waste heat boiler system, installed on high temperature flue gas pipeline, automatically controlled or cut off by receiving regulating signal. When the valve is in the closed position, there is a gap between the valve plate and the valve body to ensure the normal use during thermal expansion

The valve body with lined plate and seat. The High temperature Refractory Lined Damper Valvehas high strength, wear resistance and corrosion resistance.

The High temperature Refractory Lined Damper Valve can be designed and manufactured into a round shape according to the needs of users, so as to meet the needs of flue with different cross-section shapes. The flue baffle is equipped with manual actuator (when the diameter is not more than 900mm, it is equipped with hand wheel mechanism), pointer and 0 ~ 90 indicator board to indicate the opening degree of valve plate.

The High temperature Refractory Lined Damper Valve can withstand high temperature of 1100 ℃ without jamming and collapse

During use, the influence of thermal expansion and cold contraction of the valve will cause the stem and packing to lock, and the valve plate and valve seat to lock. Or too much residual leads to excessive leakage rate of medium. Before processing, Jinbin valve will select the appropriate material according to the temperature, and calculate the expansion amount according to the material and thickness. Under the condition of ensuring low leakage rate, the valve will not be stuck.

In the process of use, high temperature through the stem heat conduction to the top of the stem, destroy the actuator circuit or seal ring, resulting in valve necrosis. Jinbin valve will lengthen the stem, increase heat sink, reduce the damage of high temperature to the valve.

|

Suitable size |

DN100-DN4800mm |

|

Suitable medium |

High temperature gas |

|

Working Temperature |

≤1100℃ |

|

Connection |

Flange |

|

Operation |

electric actuator |

| Parts | Materials |

| Body | carbon steel+Refractory cement |

| Disc | carbon steel+Refractory cement |

| Shaft | 310S |

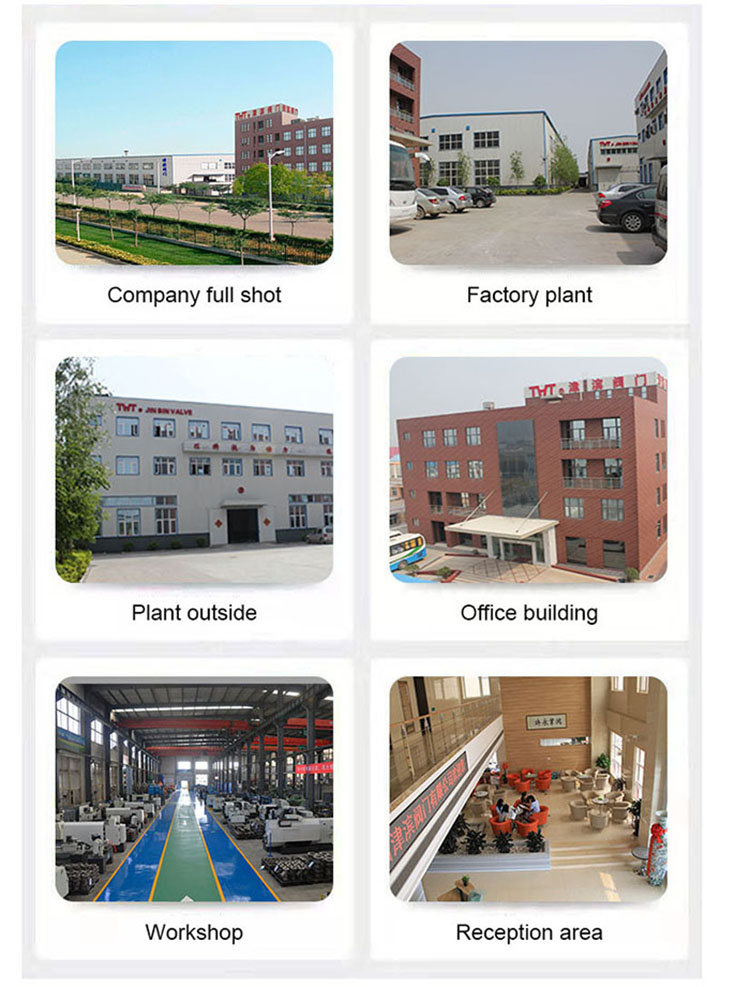

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment

Product detail pictures:

Related Product Guide:

Specialized Epic 2018: Farewell FSR Hello Single Pivot | Check Valve Dn100

Bring On the Water! 11 Watches Built for Water Sports | WatchTime | Flange Spring No Return Check Valve

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for Factory Free sample Swing Type Check Valve - High temperature round Refractory Lined Damper Valve – Jinbin Valve , The product will supply to all over the world, such as: Oman, San Francisco, Florida, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!