New Delivery for Flange Type Swing Check Valve - 200X cast iron Pressure reducing valve – Jinbin Valve

New Delivery for Flange Type Swing Check Valve - 200X cast iron Pressure reducing valve – Jinbin Valve Detail:

200X cast iron pressure reducing valve

200X pressure reducing valves automatically

reduce a higher inlet pressure to a steady lower downstream pressure, regardless of chaning flow rate and varying inlet pressure.

This valve is an accurate, pilot-operated regulator capable of holding down steam pressure to a re-determined limit. When downstream pressure exceeds the pressure setting of the control pilot, the main valve and pilot valve close drip-tight.

Size: DN 50 – DN 700

Flange drilling is suitable for BS EN1092-2 PN10/16.

Epoxy fusion coating.

|

Working Pressure |

10 bar |

16 bar |

|

Testing Pressure |

Shell: 15 bars; Seat: 11 bar. |

Shell: 24bars; Seat: 17.6 bar. |

|

Working Temperature |

10°C to 120°C |

|

|

Suitable Media |

Water |

|

|

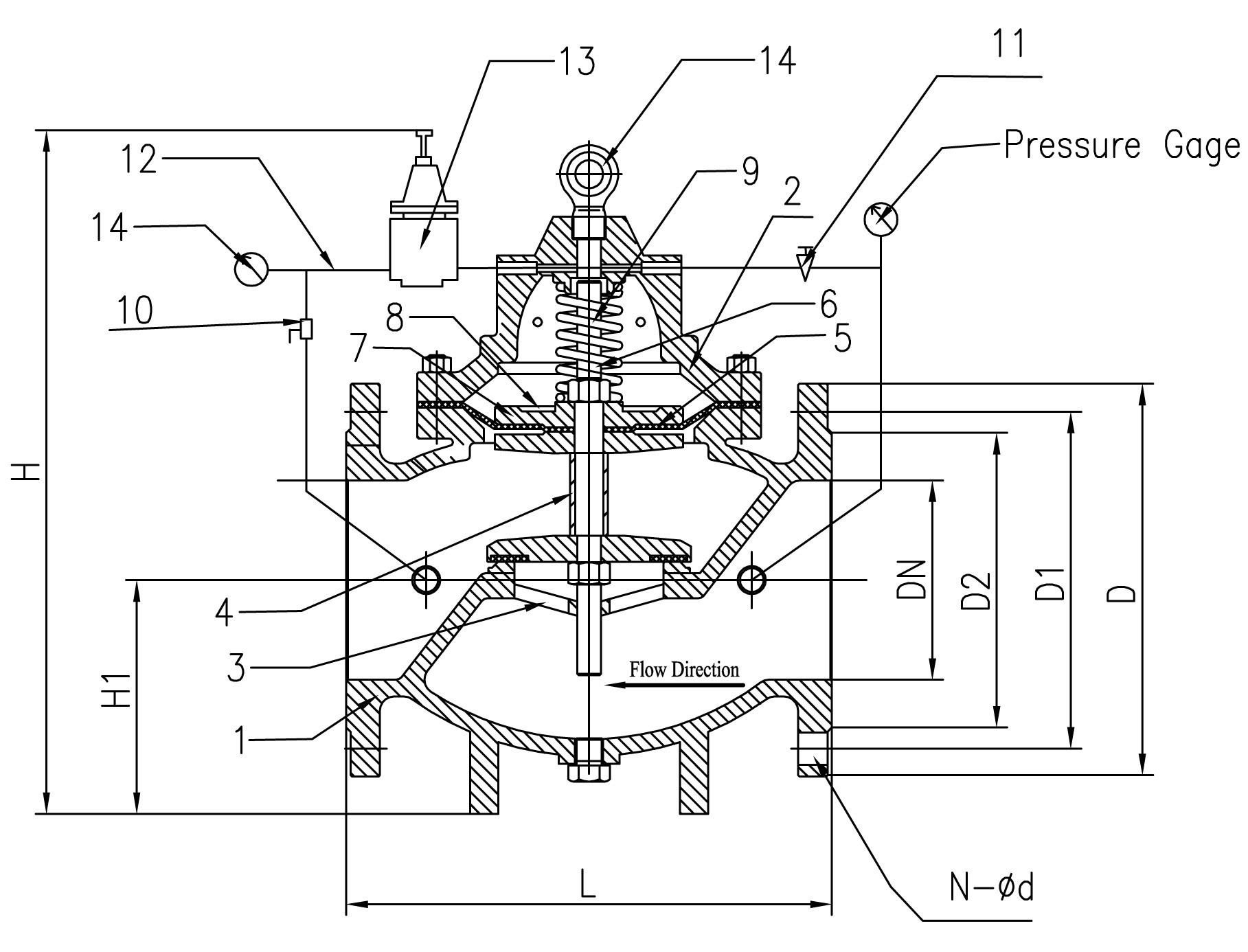

No. |

Part |

Material |

|

1 |

Body |

Ductile iron |

|

2 |

Bonnet |

Ductile iron |

|

3 |

Seat |

Brass |

|

4 |

Wedge coating |

EPDM / NBR |

|

5 |

Disc |

Ductile iron+NBR |

|

6 |

Stem |

(2 Cr13) /20 Cr13 |

|

7 |

Plug Nut |

Brass / Stainless steel |

|

8 |

Pipe |

Brass / Stainless steel |

|

9 |

Ball/Needle/Pilot |

Brass / Stainless steel |

If need the drawing details, please feel free to contact.

1. This valve adjust and maintain the maximum flow rate in outlet regardness of the change of pressure in upstream or dowenstream.

2. This kind of valve is used to adjust the flow pipe from the pump or irrigation system flow, or the flow from main pipeline to the secondary pipe system.

Product detail pictures:

Related Product Guide:

Global Industrial Valves Market 2017-2018 & Forecast to 2023 | Flange Spring No Return Check Valve

DIARY-U.S. refinery operations-Shell Says Ops Stable at Convent, Louisiana Refinery | | Check Valve Dn100

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for New Delivery for Flange Type Swing Check Valve - 200X cast iron Pressure reducing valve – Jinbin Valve , The product will supply to all over the world, such as: Canada, Sri Lanka, Romania, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly