At the beginning of the company’s establishment, JINBIN VALVE began to develop and produce various types and specifications of PENSTOCK VALVE, including various commonly used cast penstock valve and different specifications of steel penstock valve. The gate is used in many projects, such as Tianjin Airport Phase II central rainwater and sewage pump station, Panjin first sewage treatment plant reconstruction, Tianjin drainage management project and Zhongye Tiangong sewage project, etc., the steel gate includes Heze Hongyuan water supply project, Brunei sewage treatment project and Tangshan Happy Fishing Valley Project in 2016, etc.

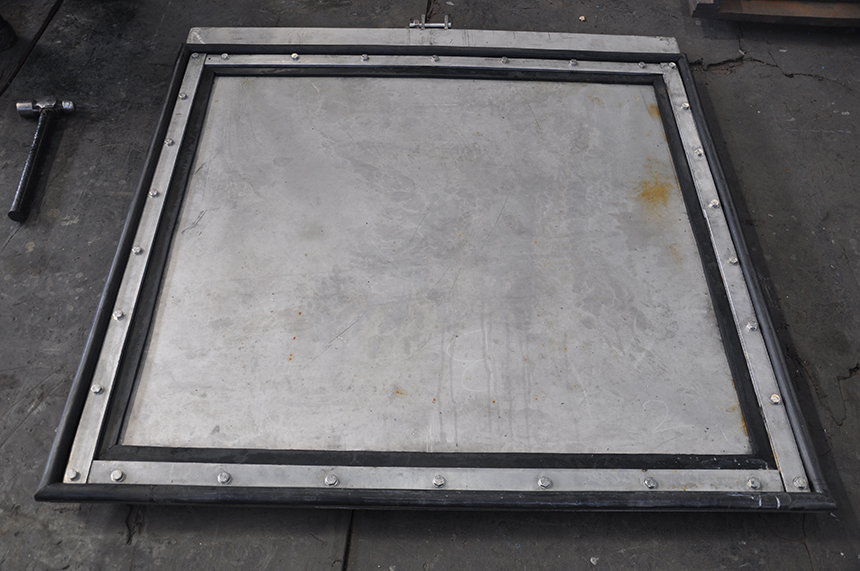

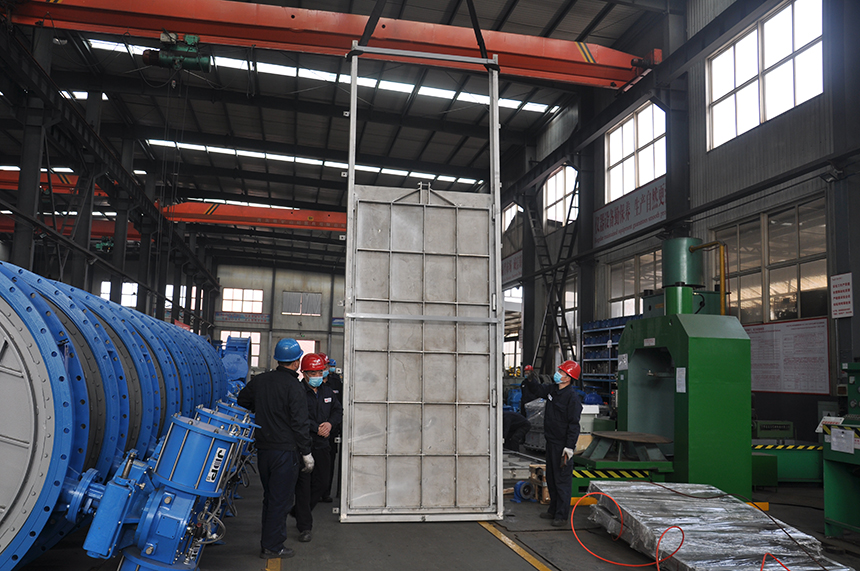

Since the beginning of the year, many orders for penstock valve have been received at home and abroad. The production department of JINBIN VALVE also devoted itself to the production. Reasonable allocation of resources, the whole process of tracking production, strict control of product quality. So far, we have successfully completed the production of 1200 * 1200 and 1560 * 3400 and other specifications of penstock valve, some of which are exported to the UK and some to Trinidad and other places. Production technicians strictly follow the requirements of drawings and specifications, from raw material mobilization – component blanking – component assembly – component welding – overall setting out – overall assembly – overall welding – shaping – anti-corrosion – finished products, each team has a clear division of labor, seamless connection before and after the process, forming a complete operation flow line, greatly improving the production efficiency.

The penstock vavle can be divided into cast iron, carbon steel and stainless steel penstock valve according to the material. Cast iron gate is cast by mould, the sealing surface is processed, and brass is used as the sealing surface, which can ensure the airtightness of gate. There are various kinds of square and round penstock valve moulds in common use. The steel gate has various specifications of square type, rectangular type and circular type, which are suitable for various occasions and working conditions, and the materials include ordinary carbon steel, stainless steel, super dual phase steel and other materials, which can be applied to anti-corrosion media.

According to the structure, the penstock valve can be divided into channel and wall penstock valve. Channel penstock valve, with fixed parts on the pentock valve, is fixed by concrete pouring between channels. Attached wall type (wall type), the penstock valve is connected with the wall by bolts.

The penstock valve is widely used in water supply and drainage engineering to cut off the water flow in the channel. Its working medium is raw water, clear water, sewage, etc. under normal temperature.

Post time: Apr-16-2020