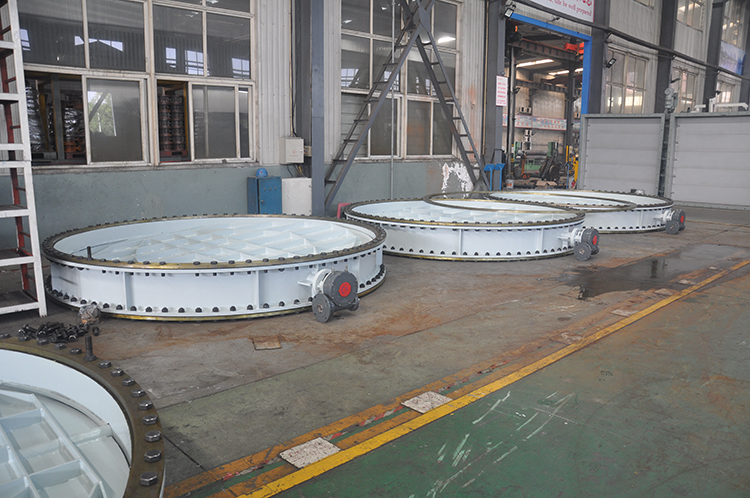

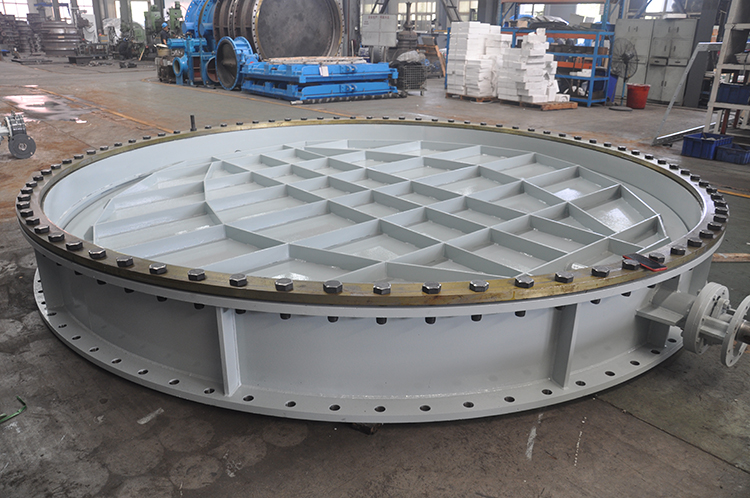

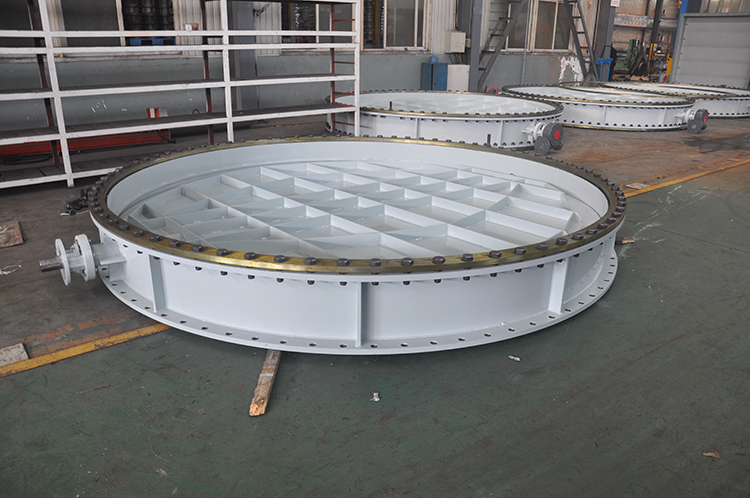

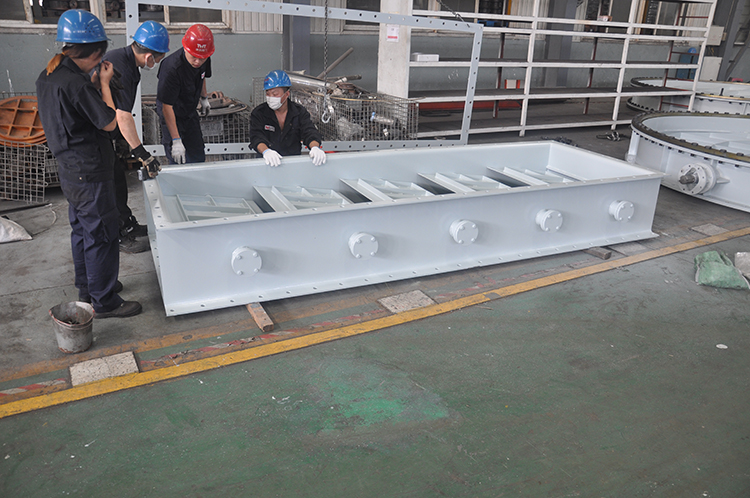

Recently, Jinbin valve has successfully completed the production of dn3900 air damper valve and square louver damper. Jinbin valve overcame the tight schedule. All departments worked together to finish the production plan.

Because Jinbin valve is very experienced in the production of air damper valve and louver damper, the technical department quickly produced production drawings. The production department also keeps communication with the technical department and works overtime to ensure the smooth delivery within the construction period. Implement the main responsibility system, highlight the key points, grasp the key points, strengthen the measures, and pay close attention to the implementation. The production departments find problems and solve them in time. The production department shall hold regular supervision and scheduling meetings to report the completion of specific work once a week and inspect once a month. All parts shall be tracked to promote production and strictly prevent delay. In the production process of the factory, master the specific processing progress of each part of the machine tool, do a good job in the connection of the upper and lower procedures, so as to avoid affecting the subsequent assembly work. For the problems found in the assembly process, timely communicate and coordinate with technical departments, so as to avoid affecting the assembly cycle.

This batch of air damper valve and louver damper were successfully delivered and passed the customer’s inspection.

The air damper valve and louver damper are used in the dust containing cold air or hot air gas pipeline of ventilation engineering in chemical industry, building materials, power station, glass and other industries, as the pipeline control device of gas medium regulating flow or cutting off.

Post time: Sep-18-2020