Slot valve is a kind of conveying pipe for powder, granular, granular and small materials, which is the main control equipment to adjust or cut off the material flow. Widely used in metallurgy, mining, building materials, chemical and other industrial systems to control material flow regulation or cutting action. So, what are the types of plugboard valves?

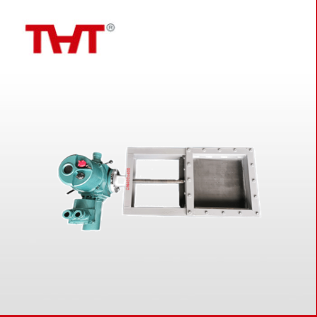

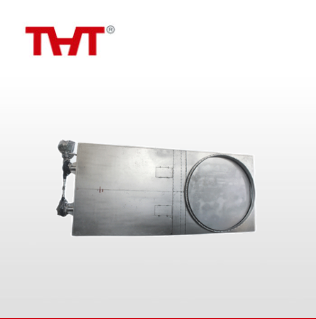

1, In general, plug valve can be divided into four types: electric plug valve, electric hydraulic plug valve, pneumatic plug valve and manual plug valve. The plunger valve is usually composed of a valve body, a valve plate, a valve plate frame, a spiral clamping drive device, an expansion joint and a valve plate traveling drive device. The valve plate is composed of a through plate and a blind plate to control the flow and cut off of the medium; The floating seat and the corrugated expansion joint are welded together, and the traveling driving device drives the valve plate frame to move, realizing the conversion between the through hole valve plate and the through hole valve plate; The clamping device drives the screw drive device to rotate synchronously through the chain drive, and the screw nut drives the floating seat to move horizontally, so that the sealing surface of the floating seat presses the O-ring on the valve plate, and the valve is sealed.

2, The function of the plug valve is simple, but indispensable. The plug valve is a simple switching function and cannot be rationed. It only provides switches for short-term maintenance and replacement of other valves and equipment, which is useful for blocking logistics. Although the cartridge valve is simple in application, it is a useful cut-off gate with simple structure and low failure rate. Easy disassembly and maintenance, affected by negative pressure, can be replaced by its own parts, does not affect the use of. Slot valves are usually used with impeller feeders. The valve is generally used at room temperature and can be customized for high temperature and corrosive materials according to the application, but the high-density valve and the air blocking valve should not be used, which will make the valve not achieve the desired effect.

3, Manual cartridge valve according to its operating structure can be divided into spiral and handle type. Generally used in conjunction with the rotary valve, it only plays the role of cutting off the ash hopper when the rotary valve is repaired, such as the dust collector’s ash hopper.

4, Pneumatic plunger valve for automatic dust control. It can be used for ash discharge of settling chamber or combustion chamber ash hopper in the dust removal system of electric furnace.

5, The electric plug valve is used for automatic discharge control of dust, mud, etc. It can be used for ash discharge of settling chamber or combustion chamber ash hopper in the dust removal system of electric furnace.

What is a pneumatic cartridge valve?

1, Pneumatic cartridge valve is a main control equipment, used to transport powder, granular materials, granular materials and small materials flow or delivery.

2, Pneumatic cartridge valve is widely used in metallurgy, mining, building materials, food, chemical and other industries to control flow change or cut off. The pneumatic cartridge valve has the advantages of simple structure, flexible operation, light weight and no jamming. It is especially suitable for the transportation and flow regulation of various solid materials, and the transportation and flow regulation of blocky and blocky materials of about 50 mm. The installation Angle is not limited, the operation is convenient, and the scale can be adjusted at any time.

3, It has the characteristics of simple structure, flexible operation, light weight, no jam, fast cutting speed, etc., especially suitable for all kinds of non-viscous solids, powders and particles less than 10mm transportation and flow regulation. The installation Angle is not limited, the operation is convenient, and the opening can be adjusted at any time.

Post time: Jul-21-2023