OEM Customized Dual Check Valve - butterfly type tilting disc flange check valve with oil cylinder – Jinbin Valve

OEM Customized Dual Check Valve - butterfly type tilting disc flange check valve with oil cylinder – Jinbin Valve Detail:

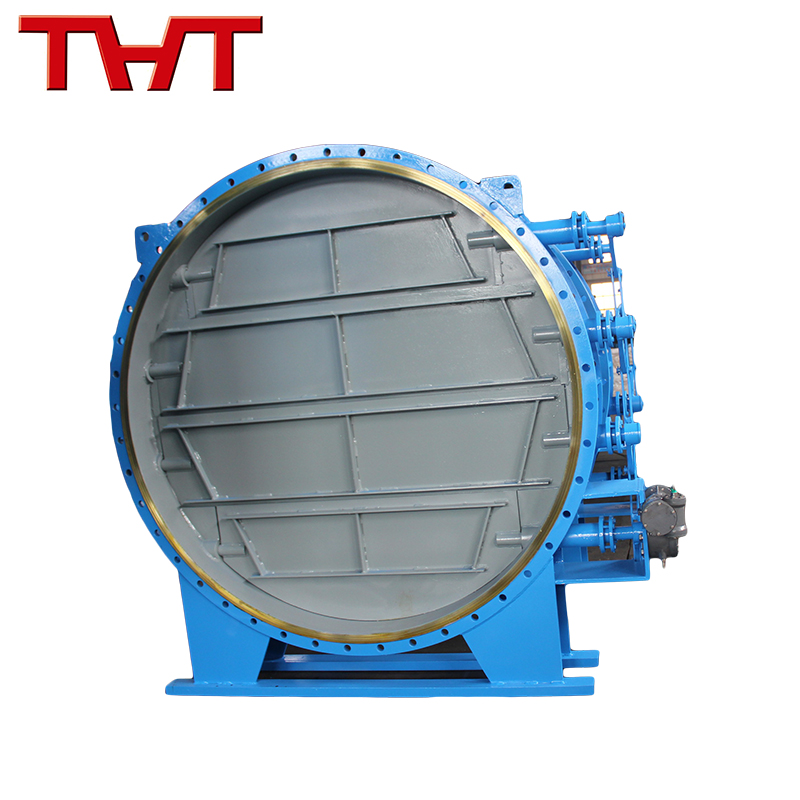

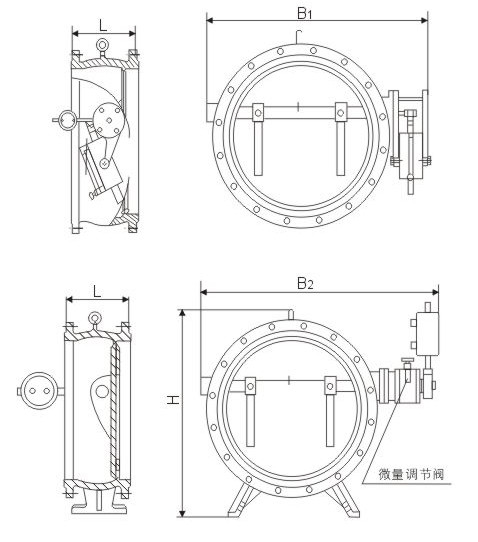

Tilting disc flange Check Valve with counterweight

For BS 4504 BS EN1092-2 PN10 / PN16/ PN25 flange mounting.

Face-to-Face dimension conforms to ISO 5752 / BS EN558 serial 14.

Epoxy fusion coating.

|

Working Pressure |

PN10 / PN16 / PN25 |

|

Testing Pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

|

Working Temperature |

-10°C to 80°C (NBR) -10°C to 120°C (EPDM) |

|

Suitable Media |

Water, sewage etc. |

Shell and seal tests for each valve is done and recorded before package to make sure the product quality. The test media is water in room conditions.

|

Part |

Material |

|

Body |

Ductile Iron/Carbon steel |

|

Disc |

Ductile Iron / Stainless Steel |

|

Spring |

Stainless Steel |

|

Shaft |

Stainless Steel |

|

Seat Ring |

NBR / EPDM |

|

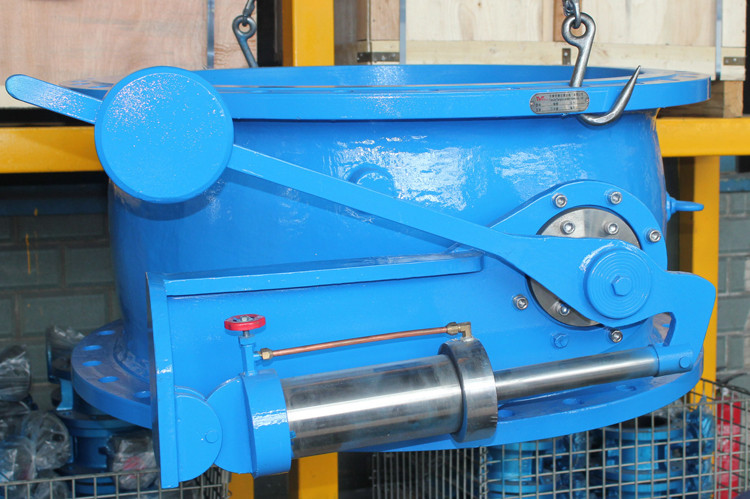

Cylinder/Piston |

Stainless steel |

If need the drawing details, please feel free to contact.

This check valve is used for preventing the back-going of medium in pipelines and equipments, and the pressure of medium will bring the result of opening and closing automatically.When the medium is back-going, valve disc will automaticaly closed to avoid accidents.

Product detail pictures:

Related Product Guide:

RHI Magnesita (LON:RHIM) Earns “Buy” Rating from Peel Hunt | Flange Spring No Return Check Valve

Lorenz Acquires Flow Valves International : Plastics Technology | Flange Spring No Return Check Valve

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for OEM Customized Dual Check Valve - butterfly type tilting disc flange check valve with oil cylinder – Jinbin Valve , The product will supply to all over the world, such as: Madrid, Belgium, Rio de Janeiro, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!