One of Hottest for Seal Gate Valve - WCB flange lift type check valve – Jinbin Valve

One of Hottest for Seal Gate Valve - WCB flange lift type check valve – Jinbin Valve Detail:

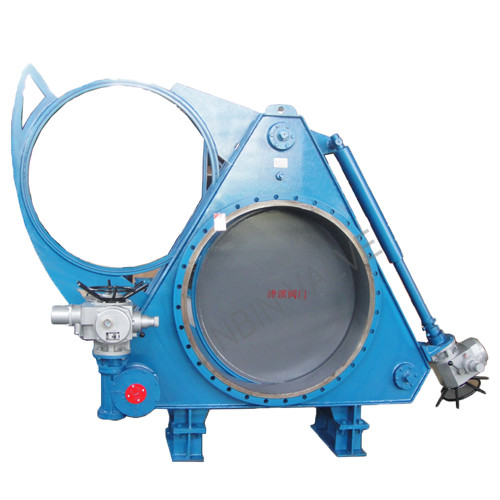

WCB flange lift type check valve

1. When the medium flows in the specified direction, the valve disc is affected by the medium force. When the medium is opened for countercurrent, the valve disc and the sealing surface of the valve seat are closed due to the self weight of the valve disc and the reverse force of the medium, so as to prevent the countercurrent of the medium.

2. The sealing surface of the valve body and disc shall be overlaid with stainless steel.

| Suitable size | DN 50– DN500mm |

| Nominal pressure | PN16, PN25, PN40 |

| Test pressure |

Shell: 1.5 times rated pressure, Seat: 1.1 times rated pressure. |

| temp. | -10°C to 250°C |

| Suitable medium | Water, Oil and gas. |

| No | Name | Material |

| 1 | Body | WCB |

| 2 | Disc | WCB |

| 3 | Stem | SS420 |

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment

Product detail pictures:

Related Product Guide:

Camshafts, Valves, And Other Intermittent Mechanisms | Grooved Butterfly Valve

Honest John’s Motoring Agony Column 27-04-2019 Part 2 | Motoring News | Flange Spring No Return Check Valve

We emphasize progress and introduce new merchandise into the market each and every year for One of Hottest for Seal Gate Valve - WCB flange lift type check valve – Jinbin Valve , The product will supply to all over the world, such as: Ottawa, Pretoria, Grenada, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.