Imbambano enzima yesango eliphindwe kabini yesango le-valiel ye-valve ye-valve ye-airbag

Imbambano enzima yesango le-Hamphulth Air moya etywiniweyo ye-valve yesango

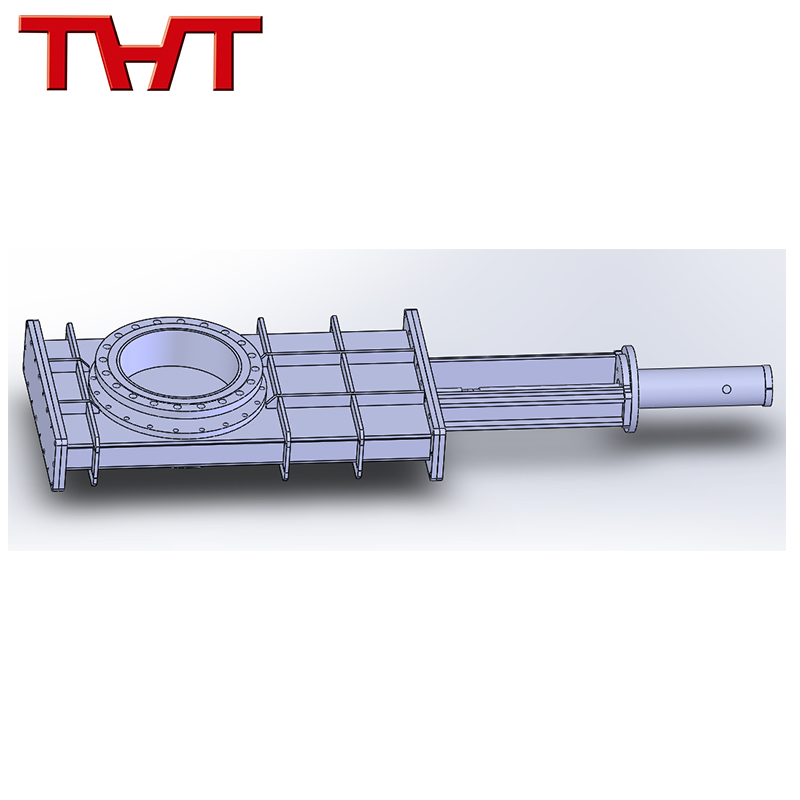

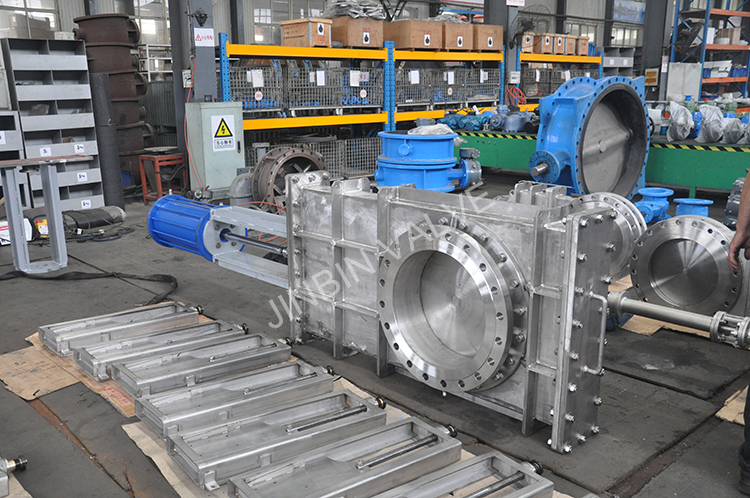

I-Air etywiniweyo ye-valve ye-valve valve valve scalfasts zifumana iindlela ezimbini ezahlukeneyo zokutywina kwimikhombandlela elungileyo nebuyiselweyo. Isakhiwo esihle sisimo esidityanisiweyo esisetyenzisiweyo, esijongwa kwi-vali ye-valit nge-PtFe Triec Sering; Ukubuyela umva kukutshintsha kwembuyekezo yokutshintsha kwendlela yokudibanisa, edityaniswe yingxowa yomoya. Ngokuphelisa umoya kwingxowa yomoya, ibhegi yomoya yenza ukuba i-Axial Shuttion ihlawulwe, i-ow yokuqala kukuqinisekisa ukuguqulwa kwenkunzi yegusha kunye nokuqinisekisa ukutywina ; Okwesibini kukunciphisa amandla egusha kunye nokuvala inkunzi yegusha: Izinto zengxowa yomoya kufuneka zithwale uxinzelelo lwangaphakathi lwe-1.6MPA nge-200 ° iqondo le-200 I-1.6MPA).

| Inqanaba lokulinganisa | Pn10 |

| Uxinzelelo lovavanyo | I-Shell: I-1.5 amaxesha oxinzelelo Isihlalo: 1.1 Amaxesha oxinzelelo olwenziwe. |

| Iqondo lokusebenza | I-200 ° C |

| I-fluid efanelekileyo | amasuntswana aqinileyo njl. |

| Hayi. | Inxenye | Isixhobo |

| 1 | Umzimba | I-SS304 |

| 2 | I-Bonnet | I-SS304 |

| 3 | Isango | I-SS304 |

| 4 | Isihlalo | I-rttfe |

| 5 | Ishafti | I-SS420 |